S-Tech Forklift Batteries 68V 205Ah includes the battery core and the controller of battery modules, furnishing power output of low- voltage system for electric vehicles

Supply Ability :

One hundred thousand units per monthOEM/ODM :

SupportCountry of origin :

Anhui, ChinaProduct dimensions :

500x320x250mmProduct weight :

410000KgStandard voltage :

68VCapacity :

205AHLead time :

A week1.Product Overview

S-Tech Forklift Batteries 62V 105Ah includes the battery core and the controller of battery modules, furnishing power output of low- voltage system for electric vehicles

1.1Product Information

| system | Version | Notes |

| Battery system | A | F80420B |

| Battery cell | F | EVE LF105 |

| Battery management system | - | LEV06S |

1.2Product Functions

1.21-The battery system is provided with the function of power output providing.

1.22-The battery system is provided with the function of monomer voltage detection.

1.23-The battery system is provided with the function of total voltage detection.

1.24-The battery system is provided with the function of temperature detection.

1.25-The battery system is provided with the function of current detection.

1.26-The battery system is provided with the function of charging overcurrent protection.

1.3Information on Battery System

| item | Unit | Specifications | Remarks | |

| Rated capacity | Ah | 420Ah | @ 0.5C ,25C | |

| Configuration | - | 25S4P | - | |

| Oper ating temper ature | Charging working temperature | ℃ | 0~55 | - |

| Discharge working temperature | ℃ | -20~55 | - | |

| Storage temperature | Short term (within 1 month) | ℃ | -20~45 | - |

| Long term (within 1 year) | ℃ | 0~35 | - | |

| Rated voltage | V | 80 | Cell 3.2V | |

| Maximum voltage | V | 91.25 | Cell 3.65V | |

| Minimum voltage | V | 62.5 | Cell 2.5V | |

| Standard capacity | KW/H | ≥33.6 | @ 0.5C ,25C | |

| Weight | Kg | 410000±25 | - | |

| Maximum discharge current | A | 450 | - | |

| Maximum charging current | A | 230 | - | |

| Continuous discharge current | A | 280 | - | |

| Continuous charging current | A | 200 | - | |

| SOC status of batterysystem before shipmentStandard Charge (@25℃ ) | - | Constant Current: ≤0.5CConstant Voltage:3.65VEnd Condition(Cut off):≥0.02C | - | |

| SOC status of battery system before shipment | - | SOC 30%±3% | - | |

| Self-discharge rate | % | Max 3 | - | |

| Safe reliability | - | GBT Certificate | cell | |

| Insulativity | MΩ | Min 20MΩ/1000VDC | @25℃±5℃, RH50% | |

| Cooling mode | - | Natural(Passive)Convection | - | |

| Heating function | - | Temperature rises by 15degrees in 1 hour. | Heatingbychargingmode | |

| - | On: Minimumtemperature ≤6degrees | |||

| - | Off: Minimumtemperature ≥15 degrees | |||

| Working range of SOC | % | 0~ 100% | - | |

| Ingress protection | - | IP65 | - | |

| Cycle life | - | >3500 | @25℃, 0.5Ccharge,1Cdischarge, DOD100%(SOC0~100%) | |

| Remaining capacity at theend of life | - | EOL 70% | Accordingtowarrantyperiod, driving pattern, temp.profile, etc | |

1.4Technical Terms

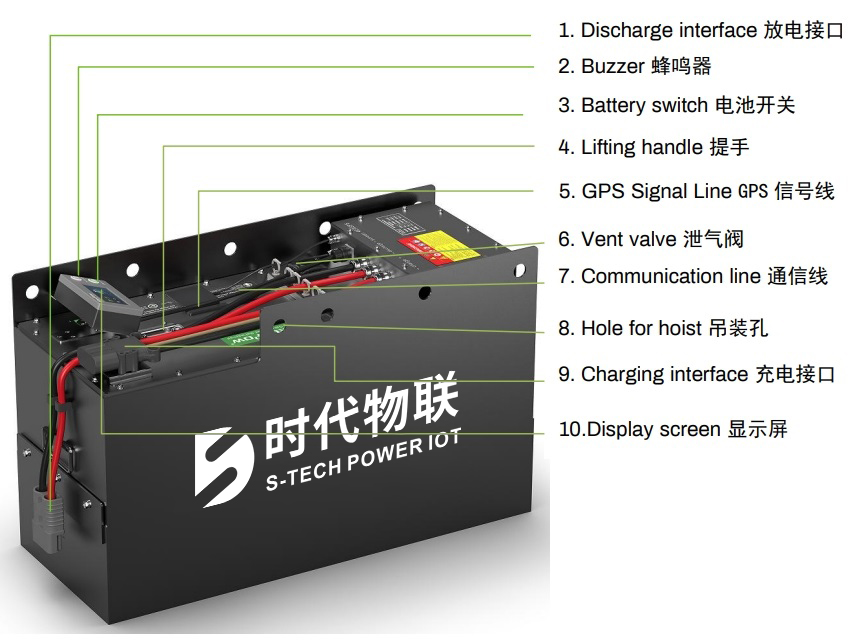

Figure 1. Schematic Diagram of Battery System

2.Assembly

2.1. Mechanical Architecture

Figure 2. Schematic diagram of battery system

| Part Name | Description | Quantity |

| Discharge interface | SB200AGrey Anderson | 1 |

| Buzzer | Buzzer | 1 |

| Battery switch | M19 self-locking switch, green light | 1 |

| Lifting handle | - | 2 |

| GPS Signal Line | - | 1 |

| Vent valve | VE-P322-00-KS1 | 1 |

| Communication line | Communication line of display screen | 1 |

| Hole for hoist | - | 9 |

| Charging interface | REMA 160A | 1 |

| Display screen | 4.3 inches | 1 |

2.2. Mechanical Interface

Figure 3. System Tolerance

Basic Dimensions

| Name | Size |

| Size of battery system | 940(L) x 800 (W) x 800 (H) |

| Charging plug wire | 600mm |

| Discharge plug wire | 1900mm |

| Communication line | 2000mm |

2.3. BMS

Parameters BMS

| Item | Standard | |

| Current | Self-discharge Current (Active mode) | ≤150mA |

| Self-discharge Current (Error mode) | ≤50mA | |

| Self-discharge Current (Shutdown mode) | ≤15uA | |

| Max Charge/Discharge Current | 200 A/ 450A | |

| System Inrush Current | TBD | |

| Over ChargeProtection | Over Charge Protection Voltage | 3.65±0.01V |

| Over Charge Release Voltage | Restart | |

| Over DischargeProtection | Over Discharge Protection Voltage | 2.5±0.01V |

| Over Discharge Release Voltage | 3.0±0.01V | |

| Charge OverCurrent Protection | Charge Over Current Protection Current | 230A±5A |

| Charge Over Current Protection Delay | 2S | |

| Charge Over Current Protection Release | Restart | |

| Discharge OverCurrentProtection1 | Discharge Over Current Protection Current | 350±5A |

| Discharge Over Current Protection Delay | 2S | |

| Over Current Release | After 5Srelease | |

| Discharge OverCurrentProtection2 | Discharge Over Current Protection Current | 450A(typical) |

| Discharge Over Current Protection Delay | 5S | |

| Over Current Release | Restart | |

| Short CircuitProtection | Short Circuit Protection Current | 500A |

| Release Condition | Replace fuse | |

| Charge OverTemperatureProtection | Charge High Temperature Protection | 60℃ |

| Charge High Temperature Release | Restart | |

| Charge Low Temperature Protection | -20℃ | |

| Charge Low Temperature Release | 5℃(By heating) | |

| Discharge OverTemperatureProtection | Discharge High Temperature Protection | 60℃ |

| Discharge High Temperature Release | Restart | |

| Discharge Low Temperature Protection | -20℃ | |

| Discharge Low Temperature Release | Restart | |

| Heater workingcondition | Heater ON when cell temperature in charging | 6℃ |

| Heater OFF when cell temperature in charging | 15℃ | |

| Heater OFF when cell temperature in charging | / | |

| Communication | CANBUS 250Kbs |

/ |

| In Parallel | Not support | / |

2.4. Information on the Power Interface of Battery System

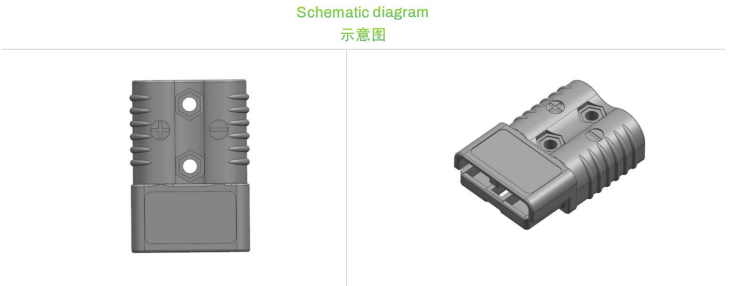

View of discharge connector

Figure 4. Schematic diagram of discharge connector

View of charging connector

Figure 5. Schematic diagram of discharge connector

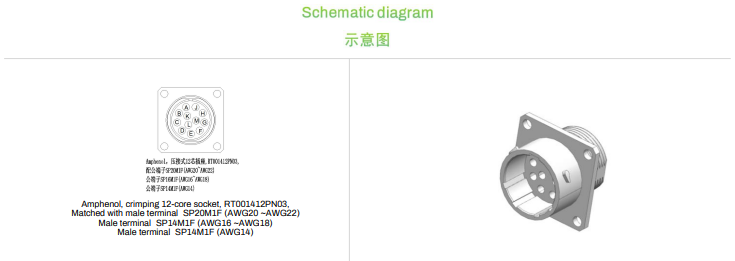

View of low voltage connector

Figure 6. Schematic diagram of low voltage connector

Distribution of pins of low voltage connector

| Pin Nc | Terminal Material | Signal |

| A | Sn | BJ1+ |

| B | Sn | BJ1- |

| C | Sn | CANH2 |

| D | Sn | CANL2 |

| E | Sn | 12V+ |

| F | Sn | 12V- |

| G | Sn | 5V+ |

| H | Sn | 5V- |

| K | Sn | SW_IN |

| K | Sn | SW_OUT |

| L | Sn | Debugging CANH |

| M | Sn | Debugging CAN |

3. Requirements for Packaging

3.1. Schematic Diagram of Packaging

Figure 7. Skematic Daigram of Pakaging

3.2 Packing List

| Part Name | Part Number | Product Specification | Package Quantity |

| Battery system | F80420B | 420Ah 25S4P | 1pcs |

| Harness ofdisplay screen | / | Plug wire of display screen | 1pcs |

| Universaldisplay screenof forklift system | S8055SD | The project includes theprotective plate ofmonochrome displayscreen, waterproof shellmaterials and adapterwires. | 1pcs |

4. Precautions and Prohibitions in the Use of Lithium-ionBattery Module

Before making use of battery modules, please be sure to read the user manual and precautionsfordealing with battery modules.

Improper operation of lithium-ion batteries may result in leakage, heating, smoking, explosionor fire.This may cause performance degradation or failure. Please be sure to operate the batteriesinstrictcompliance with the instructions carefully.

4.1. Storage

| Time | Temperature |

| Short term (within 1 month) | -20~45℃ |

| Long term (within one year) | 0~35℃ |

Store battery modules at room temperature.

Customers are required to finish incoming inspection within one month upon the arrival of goods.

4.2. Safety Precautions and Prohibitions

With an attempt to guarantee product safety, please list the following precautions in theinstructionmanual.

4.3. Electricity Abuse

4.31-Please make use of a dedicated charger

4.32-Batteries can only be used or charged on special occasions.

4.33-Reverse charging is strictly prohibited.

4.34-The charging current must be controlled at the value prescribed in the specifications of batteries.

4.35-The cut-off voltage for charging is 91.25V(3.65Vx25)

4.36-The charger must have the specifications to stop charging batteries by detecting the specifiedcut-offcurrent.

4.37-The discharge current must be controlled within the specification value prescribed by the product.

4.38-The discharge cut-off voltage must be over 62.5V(2.5Vx25)

4.4. Environmental Abuse

4.41-Never put batteries near fire or heat sources.

4.42-Never throw the batteries into the fire.

4.43-Never soak the batteries in water or seawater.

4.5. Others

4.501-Never store metal objects such as keys or screwdrivers near batteries.

4.502-Never intentionally short-circuit (+) and (-) terminals with metal objects.

4.503-Never pierce the batteries with sharp objects such as needles or screwdrivers.

4.504-Never heat a part of the batteries with heating objects such as an electric soldering iron.

4.505-Never hit the batteries with heavy objects such as hammers or heavy objects.

4.506-Never step on the batteries or drop the batteries on the hard ground.

4.507-Never disassemble the batteries or modify the design of the batteries, including the circuits.

4.508-Never directly weld anything on the batteries.

4.509-Never make use of badly scarred or deformed batteries.

4.510-Never put batteries in microwave ovens, dryers or high-pressure containers.

4.511-Never disassemble the batteries yourself.

4.512-Never put the batteries in the water.

4.513-Never expose the batteries to splashing water.

4.514-Never expose the batteries to humid environment.

4.515-Never use the batteries after a fall accident.

4.516-Please be sure to read the operating instructions of the charger before making use of the charger.

4.517-Please be sure to read the user manual of the application before installing and removing batteriesfromthe application.

4.518-Batteries or modules required to be stored for a long time should be removed fromthe applicationandstored in a suitable place at room temperature.

4.519-When charging, using and storing batteries, please keep the batteries away fromstatic objectsandmaterials.

4.6. Warning

4.61-In the event that the charging is not finished within the prescribed time, please stop charging.

4.62-If the batteries are abnormally heated, smelly, discolored, deformed or otherwise abnormal inthecourseof use, charging, discharging or storage, please stop making use of the modules.

4.63-When leakage or odor is found, please stay away from fire or heat at once. In the event that liquidleaksto skin or clothes, rinse it off at once with plenty of clean water.

4.64-Never rub your eyes in the event that liquid leaks out of the batteries and enters your eyes.

4.65-Please immediately wash your eyes with plenty of water and seek medical treatment.

4.66-In the case that the terminals of the batteries get dirty, please wipe them with a dry cloth beforemakinguse of the battery modules.

4.67-The batteries can be used within the following temperature range, not beyond the temperaturerangeof -20~55℃.

4.68-Before disposing of the terminals, please cover the terminals of batteries with appropriate insulatingtape.